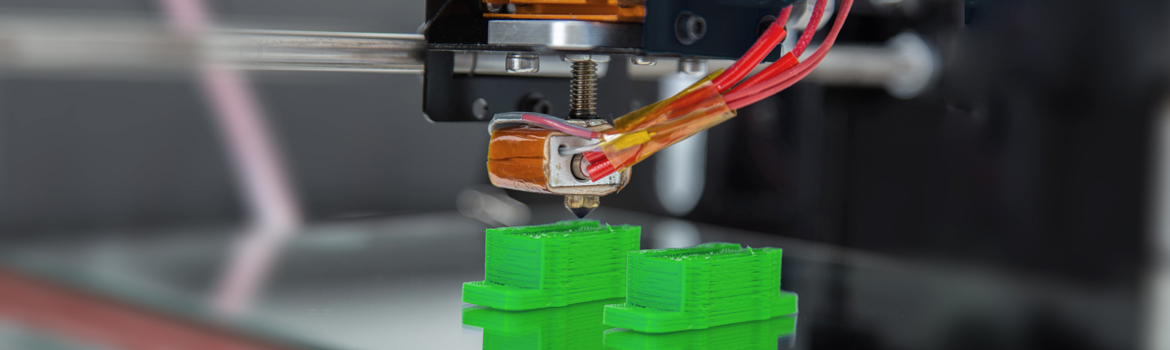

3D Printing:

perfect finishing, impregnation and sealing of porous surfaces

Capillary-active surface finishing for more color brilliance, color protection, chemical-resistance, strength and dimensional stability.

DIAMANT Dichtol is a ready-to-use impregnation system for the reliable, fast sealing of micropores, porosities, and hairline cracks in rapid prototyping. It is easy to apply by brushing Dichtol on, spraying it on, or dipping the part in the Dichtol. It will seal the part and, in most applications, improve the surface appearance. It has European approval for both food and water applications.

Product overview: Dichtol for Rapid Prototyping

| Product name | Product# | Description | Technical data sheet |

| WF 2180 | #2180 | Resistant to solvents and aggressive media | |

| WFT standard | #1532 | up to 300°C, very good penetration and chemical resistance Seals the smallest of pores |

|

| WFT standard spray | #2087 | Same as WFT standard in a 500ml spray can | |

| WFT Macro | #1546 | Allrounder up to 300°C for larger pores | |

| WFT Macro spray | #2088 | Allrounder for larger pores in the practical 500ml spray can |

Thermally, physically and chemically highly resistant

Conventional sealants used in 3D Printing protect only to a certain extent, since they are limited to the surface. Dichtol from DIAMANT POLYMERS INC, conversely, penetrates even the smallest of pores and as a result impregnates the treated surfaces in depth – in addition to sealing and impregnating the surface. Apart from the surface finish, DIAMANT Dichtol thus also improves the fundamental properties of the workpiece, such as the strength of brittle materials and the dimensional stability of the part. In the capillary-active impregnation with Dichtol, a highly resistant polymer is applied to the porous surface. Thanks to the outstanding capillary activity of Dichtol, the polymer penetrates deep into the workpiece and hardens there. The hard-elastic high-performance polymer anchors itself in the treated part and reliably seals it, even if temperatures vary. DIAMANT Dichtol is extremely resistant to physical, chemical, and thermal stresses. The technical properties of the workpiece are fully retained.

Brushing, spraying, injecting or dipping

Dichtol adapts itself versatilely and flexibly to the respective conditions of use in 3D Printing: the polymer system can be applied equally well by simply brushing, spraying, injecting, or dipping. It reliably seals pores up to a diameter of 0.5 millimeters.

Dichtol: convincing properties, decisive advantages

- wide range of application possibilities by

- dipping

- brushing

- injecting

- spraying

- ready to use and easy to apply

- individual and series impregnation possible

- low investment costs

- Colorless

- can be painted over

- resistant to aggressive solvents, alkalis, and acids

- resistant to corrosion and weathering

- application without pressure or vacuum

- efficient material consumption

- short drying time

- location-independent, usable everywhere

- simple application without special knowledge

- drinking water approval

- food approval