The liquid shim! 100% form and force-locking gap compensation for steel and bridge construction

First metal-polymer with general building authority approval. Safe, efficient, load-bearing, durable, economical.

Video

The polymer-bound metal MM1018 ensures a 100% force-fit, full-surface gap compensation between metal elements under load, such as:

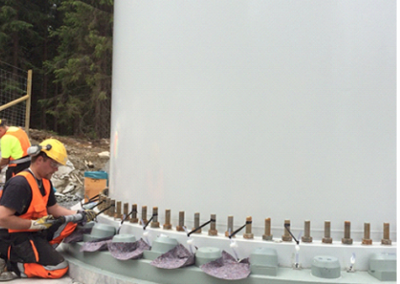

- bridge bearings

- machine foundations

- bearing seats

- face plates

- sluice gates

- beam connections

- diagonal connections

- flange connections

Tolerance compensation on the spot. In a single work step.

- directly on the spot on the structure

- in a single work step

- without the use of stiffeners or wedge plates

- without machining

DIAMANT MM1018 thus saves a considerable amount of time and personnel costs in comparison with conventional methods of gap compensation – with much greater flexibility, sustainability, and cost-effectiveness.

For targeted use: MM1018 paste or liquid

- Paste. For the compensation of gaps between two joint surfaces that are not yet permanently joined to each other.

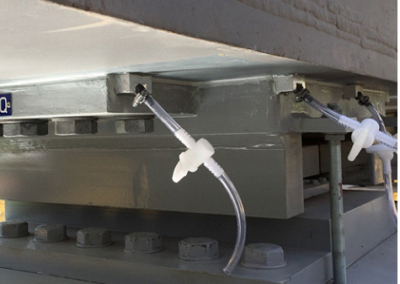

- Liquid. For “reactive” application for the subsequent compensation of gaps in already assembled steel structures.

MM1018: convincing properties,

decisive advantages

- 100%, full-surface and force-locked gap compensation from 0 to 140 millimeters

- corrosion resistant

- sea water resistant

- resistant to petrol, oils, coolants, lubricants

- resistant to weathering

- resistant to aging

- electrically non-conductive (no contact corrosion)

- vibration damping

- high compressive strength even under extreme conditions, such as vibrations or temperature fluctuations from -40 to +90 °Celsius

- extremely low shrinkage

- low creep coefficient

- no mechanical adaptation necessary

- preventively or subsequently applicable by injection (therefore also usable without disassembly of the joint surfaces)

- no complex mechanical adaptation of flange surfaces, for instance by milling or grinding

- usable without special preparation work or aids

- no time-consuming and cost-intensive mechanical adaptation and rework necessary, for instance through stiffeners and wedge plates

- application direct on the spot on the structure

- replaces otherwise necessary stiffeners or wedge plates

- building authority approval abz, DB (German Railways) approval

Contact us

In use all over the world with building authority approval

With over 1,000 applications worldwide, DIAMANT MM1018 is considered the best proven polymer system for force-locked gap compensation – and is the first product of its type to be issued with the general building authority approval from the German Institute of Building Technology (DIBt).

Beyond that, DIAMANT MM1018 is recognised by the German Railways (DB) and Waterway Authorities (WSV) and mentioned in installation regulations. The use of DIAMANT MM1018 is also described and specified in the VHFL guideline no. 2 (VHFL = Association of Manufacturers of Road Crossings and Bearings).